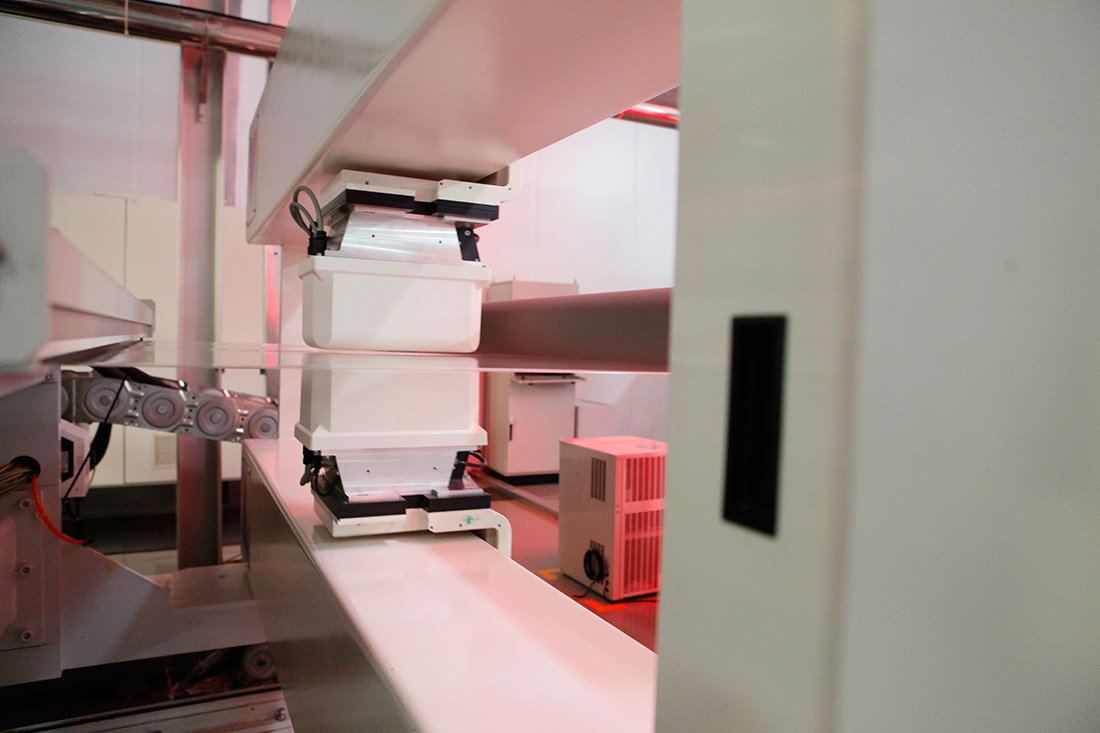

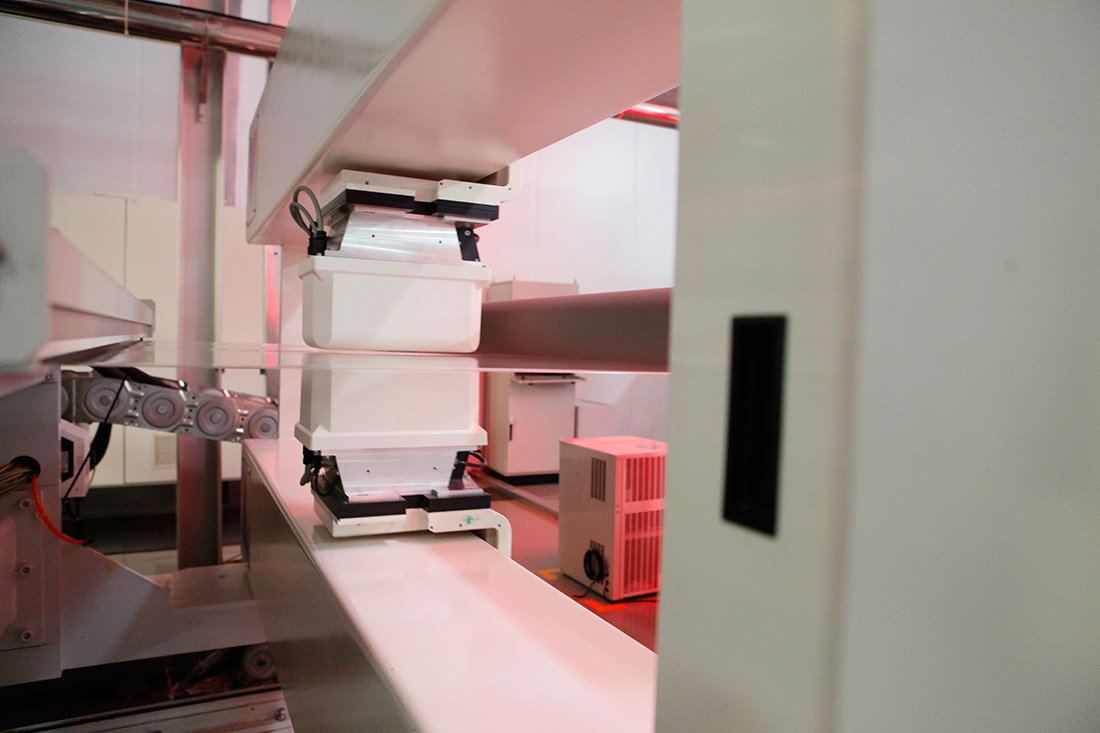

The dry uni-axial stretching separator product uses high-purity PP raw materials, manufactured through optimized production processes and high-precision imported equipment. Its uniform pore size distribution and multi-layer structure can effectively prevent internal short circuits. It is suitable for applications in electric vehicle power batteries and energy storage.

Good safety performance: The multi-layer composite separator that can effectively reduce the potential safety hazards caused by the single-layer separator defects (crystal points, holes, and impurities); no transverse heat shrinkage, and low longitudinal heat shrinkage; high-temperature resistance, and oxidation resistance, especially suitable to the high voltage system; high mechanical strength and puncture strength.

Good uniformity performance: The world’s advanced dry uni-axial stretching process is adopted to ensure consistency in thickness and the pore size, as well as uniform pore size distribution; the use of a multilayer film composite structure makes the separator product more consistent in thickness, beneficial to improve the battery cycle performance.

Good air permeability: Low tortuosity of the aperture is suitable to the demand of the power battery rate discharge.